by : (www.contrado.co.uk)

Satin Definition

So, what is Satin? First and foremost, it is not a raw material. Satin is a type of weave, constructed by floating several warp yarns across the weft before going under 1 weft thread, and beginning the cycle again. Having fewer interlaces leads to the smooth, lustrous surface we all know and love.

Satin weave is a more complex weave as the arrangement of warp and weft threads are staggered due to the step number. Unlike a Twill weave, where the weft intersections move to the next parallel warp on the following row, Satin weave structures move the weft intersection across at least 1 warp thread before beginning the cycle again.

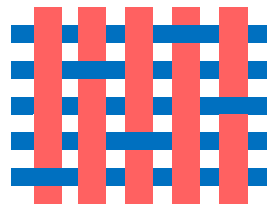

Fig A is a basic 5 end, 4/1 satin weave, warp float facing. Notice how the warp floats over 4 wefts, goes under 1, over 4, under 1, over 4, under 1 etc. A satin weave will always be: Over X, Under 1. It’s this reason why the front is smooth and the reverse of a satin fabric is matte and dull, because that’s where the weft threads are predominant. The step number here is 1 – on the next row, the weft intersection has moved 1 warp across.

Fig A; basic 4/1 satin weave, warp-float facing

Fig A; basic 4/1 satin weave, warp-float facing

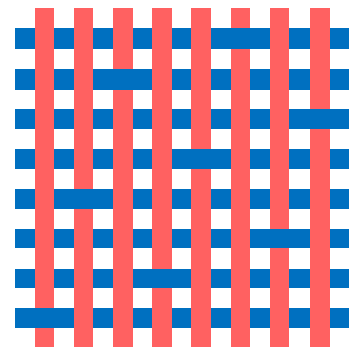

Fig B is an 8 end, 7/1 satin weave, warp float facing. The step number here is 2 – on the next row, the weft intersection has moved 2 warps along.

Fig B; warp-float facing 7/1 satin weave, step number 2

Fig B; warp-float facing 7/1 satin weave, step number 2

What is Satin Made From?

It depends if you’re a purist or not. If you’re producing a satin weave using filament fibres such as silk, nylon or polyester, then your resulting fabric is a Satin. However, there’s some definitions that insist a Satin fabric can only be made from silk. Now it can get a little confusing…

Difference Between Satin & Sateen

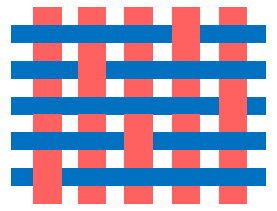

If you’re using cotton, which is a short-staple yarn, for your satin weave, the fabric you produce is Sateen. Many people often mistakenly use Sateen to describe what is Satin, not knowing that the difference lies in the yarns you use. Satin weaves are predominantly warp float facing, whereas Sateen is weft float facing – see Fig C.

Fig C; weft-float facing sateen weave

Fig C; weft-float facing sateen weave

Difference Between Silk & Satin

Duchess Satin

Duchess Satin

As discussed, Satin is a type of weave and not a material, whereas Silk is a raw material produced by silk worms that is used to make fabric. You can use silk to make Satin, as the word Satin is merely referring to the type of weave structure. Silk Satin fabric is a more expensive type of Satin, so if you’re looking to mass produce clothing or furnishings at an affordable rate, you can make Satin using polyester, nylon, rayon, or wool. Despite what you may think, Silk Satin will still have the matte, dull reverse typical of any Satin fabric.

Satin Fabric Origins

The word ‘Satin’ actually comes from ‘Zaitun’, the Arabic name for the Chinese port Quanzhou, where this weave first originated over 2,000 years ago. At the time, the cultivation of silk was widespread, so even peasant women used silk to master the craft of satin weaving, and silk clothing was not restricted to upper classes. However, China’s closely guarded satin secret eventually spread across Asia and further west.

In the 12th century, Italy became the first western country to produce satin, and by the 14th century, it became available all throughout Europe. However, using silk made the fabric costly so it was reserved for aristocracy, the church and upper classes.

What is Satin Used For?

Lucent Satin

Lucent Satin

Historically, satin was a desired fabric for upholstery, with Louis XIV using it to cover his ornate furniture in the Palace of Versailles. It was not commonly used for dressmaking until the 1800s, but soon became sought after for a luxury, ‘one time only’ evening gown amongst women of upper and working classes. The 19th century also saw satin adorn the nude bodies of fashionable Parisian women in the form of sexy lingerie. Once attributed to prostitutes in the French capital, satin experienced normalisation through journalism and advertising, which promoted the notion that luxurious underwear is important. Fast-forward to the 21st century and satin is a widely available fabric that’s mainly used for apparel, upholstery and bedding. And what’s important is that it’s still retained its association with luxury. Some common uses for satin fabric include, but are not limited to; evening gowns, shirts, corsets, underwear, inner lining, wedding dresses, loungewear, hats and ties.

Advantages: Satin Fabric

- Luxury feel and aesthetic

- Floaty drape

- Versatile

- Smooth, lustrous surface

Disadvantages: Satin Fabric

- Frays easily

- Prone to snagging

- Tricky to sew

- High maintenance

Types of Satin

Monroe Satin

Monroe Satin

Antique: heavy fabric with a dull lustre. Woven with uneven slub yarns.

Uses: Upholstery e.g. curtains.

Baronet: Most lustrous satin weave. Rayon warp and cotton weft. Often found in bright colours.

Uses: Decorative fabric, cushions etc.

Charmeuse: Highly lustrous face, very dull reverse. Quite clingy with soft draping. Hard twist yarn

warp and crepe yarn weft.

Uses: Dressmaking.

Crepe-back: Reversible fabric in that each side has either the satin weave or crepe weave visible.

Uses: Dressmaking.

Duchess: Heavy, stiff, low lustre satin. Holds its shape well. Dyed in solid colours.

Uses: Bridal wear.

Lucent: Shiny, high lustre, shimmering double faced sateen. Slippy surface.

Uses: Clothes and bags linings, fashion accessories.

Messaline: Light, soft satin. Normally made from rayon or silk. 250+ ends per inch. High lustre.

Uses: Dressmaking.

Monroe: Medium weight, sateen faced weave. Lovely drape. Tight weave holds in warmth.

Uses: Accessories, bags, bridal accessories.

Panne: Super high lustre due to heated roller pressure. Stiff finish. Normally made from silk.

Uses: Dressmaking, evening wear.

Slipper: Lightweight with matt surface, cotton reverse.

Uses: Craftwork, dressmaking.